Immersion Heater and Trace Heating Products

Specialist electrical services to the sprinkler and trace heating industry.

We manufacture and supply sprinkler tank immersion heaters which are built to LPC requirements and trace heating control systems to BS12845 to many of the industry leaders both at home and abroad.

Our 3Kw sprinkler tank immersion heater comes with a 2 year guarantee, giving our customers total piece of mind, and with all major heater components in stock we can supply replacement parts if required.

Immersion Heater 3kW

The LPC Requirements State That

- The heater must not burn out when exposed to air (e.g. when the tank water level is below the immersion heater).

- It must be of dual element type, each capable of operating independently.

- It must be capable of being maintained without the need to drain the tank.

To comply with these requirements we have introduced the following features:

An Immersion Heater Complete With:

- Two separate independently operable, withdraw able elements each 840mm long.

- Each element rated at 1.5kw 240volt single phase.

- Both elements enclosed in a stainless steel tube complete with 2.25” BSPF (ext) boss to allow the elements to be removed, if necessary, without lowering the tank water level.

- An enclosed thermal cut out set to operate if the element temperature exceeds 70oC. The cut out will re-set when the temperature drops to a safe value.

- A weatherproof IP 55 enclosure containing, 5.1) An air temperature sensor set to operate when the ambient air temperature falls to 5oC. 5.2) A triple pole interlocked isolating switch, to also isolate the test circuit, this conforms to the IEE regulations for switching and isolation of immersion heaters. Reg 554-05-03.5.3) All necessary terminations including an earth stud to allow bonding to the tank.

Although an air temperature sensor is not specified by the LPC it has been incorporated in the heater in order to save energy and therefore reduce running costs by turning the heater off when the ambient air temperature is above 5oC.

Immersion Heater Test Units

Operation

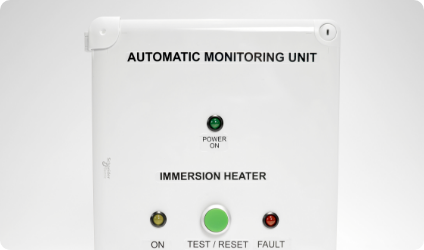

The system is fully automatic and needs no day to day adjustment or setting Procedure. With the mains connected and power on lamp illuminated the units are operated automatically when the air temperature drops below 5oC, this is achieved by the externally mounted thermistor probe within the immersion heater.

Under normal operating conditions the heater on lamp will be illuminated and the current being drawn by the immersion heater will be indicated on the ammeter.

Should the air temp be above 5oC and the unit is in stand-by mode the power on lamp only will be illuminated and no reading will be shown on the ammeter.

To test immersion heater when unit is in stand-by mode, press the green test button. After about 2 seconds the ammeter will show the current being drawn and the heater on lamps will illuminate. Releasing the button will return the unit to stand-by.

Maintenance

The units require little or no maintenance, the switchgear, contactor and M.C.B. should be maintained as normal for this type of equipment.

A periodic test of the equipment can be carried out by pressing the green test button.

The units are rated single phase 240 volts A.C. input.

All contactors are rated at 20 amps.

Ammeter and M.C.B. are rated at 16 amps.

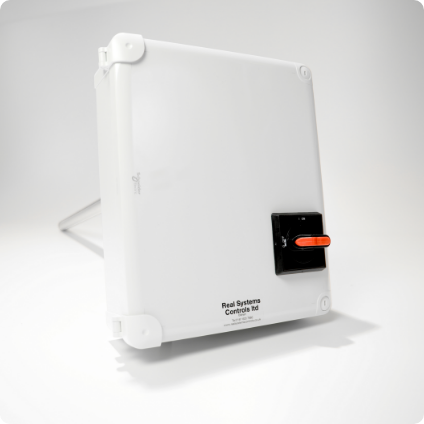

Immersion Heater Automatic Monitoring Unit

Our automatic monitoring unit for immersion heaters is fully automatic and monitors the integrity of the immersion heater every 2.5 hours. If a fault is detected, the red fault LED will illuminate on the front of the unit, and the fault relay will operate. This fault relay can be wired to any alarm system or BMS to signal a fault.

Manual Single / Dual Test Monitor Unit

The Real Systems Manual Dual Test Monitor Unit is designed to prove that the immersion heater and trace heating and operational, even when the ambient air temperature is more than 5 degrees Celsius, and the controlling thermostat is in the open position.

Capacitor Tripping Unit

The Real Systems Controls capacitor tripping unit has a 5amp, 3 way input / 2way output screw cable terminal blocks, earth chassis connection and stand off pillar mounted in an IP54 category Himel sheet steel enclosure with removable chassis plate, bottom gland plate and deep, loackable hinged front panel incorporating a white traffolyte fascia label and 130 volt LED amber indicator lamp and push button test facility.

On Site Services

Industrial and commercial electrical installation and maintenance.

Sprinkler Tank Immersion Heater installation and repairs. Trace

heating systems installation and maintenance.